Manufacturing Process

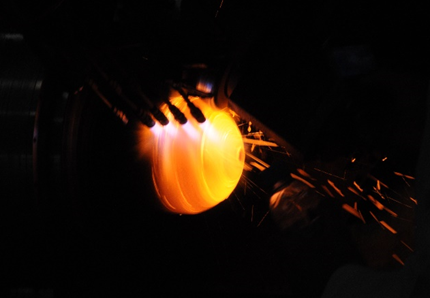

- Seamless Pipes are cut to the specified length as per requirement. The end portion of the pipe is pre-heated to make the shape of cylinder bottom by spinning, using a natural gas and liquid oxygen. It is then cleaned from inside to remove any residue or debris.

- The same Process is followed to form the cylinder top.

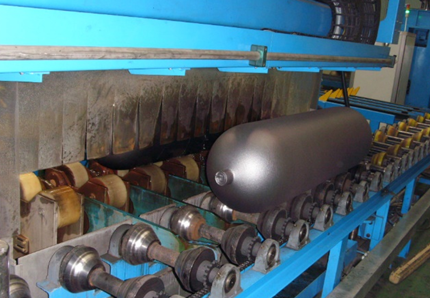

- To increase strength and durability, all cylinders are heat-treated with a specialized quenching and tempering process in the furnace.

- Quality Checks are done using Ultrasonic waves to detect any microscopic defects.

- A valve opening is created at the top of the cylinder.

- To ensure smooth finish, the cylinders are then shotblasted both internally and externally with fine balls.

- After hydrostatic test and stamping, cylinders are moved for a second external shot blast.

- Final finishing of the product is achieved after powder coating and passing through heating oven.

Pipes

Pipe Cutting

Bottom Heating

Bottom Spinning

Bottom Forming

Bottom Facing

Leakage Test

Top Spinning

Heat Treatment

1st Exterior Shot

UT Test

Hardness Test

Neck Threading

Surface Inspection

Hydrostatic Test

Air Leakage Test

Stamping

2nd Exterior Shot

Internal Shot Blasting

Painting

Painting

Finished Products

Packing